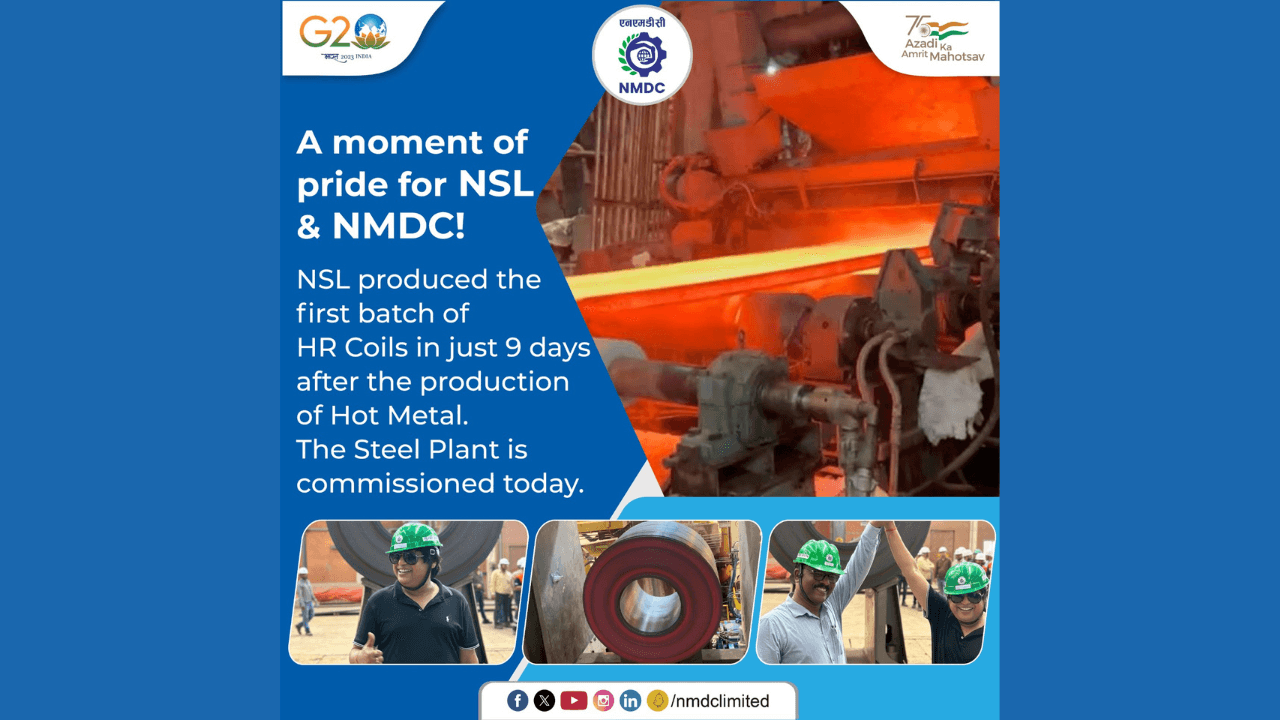

In an extraordinary achievement that is being widely discussed within the steel industry, the Nagarnar Steel Plant has accomplished an unprecedented milestone. The plant successfully produced its ultimate product of Hot Rolled (HR) Coil just nine days after the production of Hot Metal. This remarkable accomplishment by NMDC is truly remarkable, particularly when considering that the mining major did not possess prior experience in the field of steel manufacturing.

Significance

“NMDC has now joined the esteemed league of Indian steel manufacturers. This achievement fulfills a long-awaited dream of the local community in Bastar. Industry experts have noted that it is a rare accomplishment to successfully commission three crucial units in the hot zone – the Blast Furnace, Steel Melting Shop, and the Mills (Thin Slab Caster – Hot Strip Mill) – within such a short span of time.”

About Nagarnar Steel Plant

The Nagarnar Steel Plant, with a capacity of 3 million tonnes per annum, has been constructed at an approximate cost of ₹24,000 crores. This plant is poised to make a significant impact in the hot-rolled market by offering a range of high-grade Hot Rolled (HR) steel. This steel is tailored to meet the demands of various important industries, leveraging its advanced technology, including its state-of-the-art Mill. An additional advantage of the Nagarnar Steel Plant is its close iron ore supply connection with the Bailadila mines, located just around 100 kilometers away.

Products

- The product lineup of the Nagarnar Steel Plant encompasses low carbon steel, HSLA & Dual Phase Steel, and API quality steel.

- This array can be rolled into thicknesses ranging from 1mm to 16mm. The Thin Slab caster at the Nagarnar Steel Plant boasts a remarkable capability of rolling 1650 mm wide HR, making it the widest Mill within the public sector.

- The HR Coils, Sheets, and Plates produced by India’s newest and most advanced mill are anticipated to fulfill the growing demand for high-quality HR steel, needed in the manufacturing of diverse products such as LPG cylinders, bridges, steel structures, ships, large-diameter pipes, storage tanks, boilers, railway wagons, and pressure vessels.

- This HR steel is also vital in the construction of tanks, railway cars, bicycle frames, engineering and military equipment, automobile & truck wheels, frames, and body parts.

- The plant is also slated to manufacture a specialized type of steel to be used in the production of generators, motors, transformers, and automobiles in the future.

Unique Features

- For the first time, a Hot Strip Mill with Thin Slab Caster has been installed in a PSU Steel Plant, specifically designed for the production of HR Coils, a crucial component in the creation of value-added steel products.

- Driven by energy-efficient and cutting-edge technology, the energy consumption of this Plant is anticipated to be 5.9G Cal/T, showcasing its commitment to sustainability.

- Furthermore, this integrated steel plant takes a significant step towards environmental responsibility by adopting a Zero Liquid Discharge approach. This means that effluent water generated is treated and recycled, minimizing environmental impact.

- The Nagarnar Steel Plant is also equipped with the latest Wagon Tippling arrangement, designed to handle DFC Wagons in the future, ensuring its readiness for upcoming advancements in the transportation sector.

- This steel plant stands out for its eco-friendly features, such as the inclusion of environmentally conscious coke-oven batteries and a recovery-type CDCP.

- Additionally, it boasts the distinction of having the single largest coke-oven gas-handling By-Product Plant, further contributing to its environmental initiatives.

- In terms of automation, the Plant is equipped with a Converter featuring a completely automated material handling system in the BOF Shop, streamlining operations and improving efficiency.

- Furthermore, the Plant is taking steps to establish a Power Blowing Station that relies entirely on 100% CO gas, a move that aligns with its commitment to reducing the use of fossil fuels and promoting cleaner energy sources.

Domestic Steel Industry calls it an unprecedented achievement

The Nagarnar Steel Plant holds a remarkable distinction on the global stage as the only steel plant established by a mining company. The recent achievement of producing the first Hot Rolled coil within just nine days of hot metal production, which commenced on August 15th, has further solidified its reputation as an industry trailblazer.

Rapid Steel Production

Notably, the Nagarnar Steel Plant had already conducted cold trials of its Steel Melting Shop prior to initiating the commissioning of the blast furnace. While there have been instances of rapid steel production, the Plant’s achievement of producing HR Coil within nine days of hot metal production is indeed exceptional. This accomplishment was made possible through meticulous planning and testing, including rolling slabs and producing HR Coil even during the preparatory phase for the commissioning of the blast furnace.

Stabilization of Blast Furnace

Typically, the stabilization of blast furnace operations takes several weeks, followed by the synchronization of blast furnace production with the functioning of the Steel Melting Shop. This process demands caution due to the potential risks involved. The fact that this complex synchronization was achieved in such a short timeframe reflects the utilization of cutting-edge equipment and technology, as well as the expertise of the professionals involved.

HR Coil Production

With the successful initiation of HR Coil production, the Plant is now focused on stabilizing the production process to ensure its products can be commercialized at the earliest. This rapid commercialization strategy is anticipated to significantly mitigate, or even offset, the losses that are commonly incurred by new steel plants during their initial year of operation. This achievement highlights the Plant’s commitment to efficiency, innovation, and its determination to make a swift impact in the steel industry.

- Weekly Current Affairs 2025 PDF For Bank, SSC, UPSC Exams

- Unsung Heroes of India: 10 Unknown Freedom Fighters You Should Know

- 26 December Current Affairs 2023 in English

- Daily Current Affairs 2025, Check Today’s Current Affairs

- April Month Current Affairs 2024, Download PDF

- June Month Current Affairs 2024, Download PDF

Hello, I’m Aditi, the creative mind behind the words at Oliveboard. As a content writer specializing in state-level exams, my mission is to unravel the complexities of exam information, ensuring aspiring candidates find clarity and confidence. Having walked the path of an aspirant myself, I bring a unique perspective to my work, crafting accessible content on Exam Notifications, Admit Cards, and Results.

At Oliveboard, I play a crucial role in empowering candidates throughout their exam journey. My dedication lies in making the seemingly daunting process not only understandable but also rewarding. Join me as I break down barriers in exam preparation, providing timely insights and valuable resources. Let’s navigate the path to success together, one well-informed step at a time.